Reliable, high efficiency performance with highly engineered API pumps for critical upstream and downstream services.

Highly reliable with a long life, Marelli multi-stage pumps are capable of reaching massive flow rates and pressures. They are ruggedly designed to run continuously for years with rugged rotor designs and low vibration balanced rotor designs. They are efficiently designed to save energy and meet exacting API 610 and ISO 13709 standard requirements for overhung, between-bearings and vertically-suspended centrifugal pumps.

Process engineers utilize Marelli heavy duty pumps for refining, petrochemical, offshore, floating production storage and offloading (FPSO) operations, floating liquified natural gas (FLNG) facilities, chemical and general industries requiring high-pressure and flow. These pumps were originally manufactured under the Marelli Bombas brand in Spain. The install base of Marelli pumps is over 10,000 units, many running for decades.

Large engineered water pumps for refining cooling towers, raw water intake, water transfer, irrigation and large osmosis plants are also designed and manufactured in the Illescas, Spain facility.

With flows as high as 66,000 gpm (15,000 m³/hr) Marelli has a pump that will fit your application.

Common Marelli Pump Applications

- Hydrocracking

- Topping

- Gas Condensate

- HDS

- Merox LPG

- Amine

- Sour Water Stripper

- Coker

- Platformer

- Tank Farms

- Condensate Extraction

- Process Charge

- Desalination

- Fertilizers

- Oil fields and terminals

- Reverse osmosis

- Synfuels

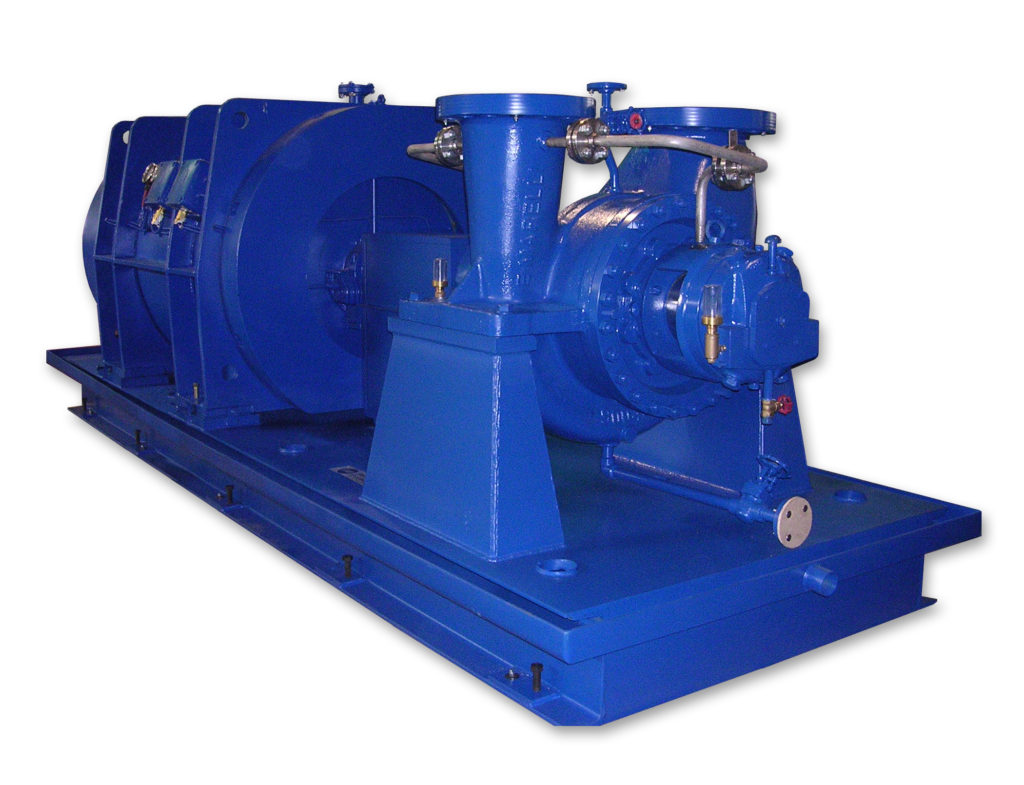

API BB1 centrifugal pump, axially split case, 1 or 2 stage pump with bearings on both ends of the rotating assembly.

- Flows to 27,298 gpm (6,200 m³/hr)

- Heads to 650 ft (200 m)

- Maximum Power 2,012 HP (1,500 kW)

- Maximum Suction Pressure 130 psi, (9 bar)

- Temperature Range -22 to 302°F (-30 to 150°C)

API BB2 centrifugal pump, radially split case, 1 or 2 stage, with bearings on both ends of the rotating assembly.

- Flows to 13,208 gpm (2,400 m³/hr)

- Heads to 1,640 ft (350 m)

- Maximum Power 2,011 HP (1,500 kW)

- Maximum Suction Pressure 290 psi (20 bar)

- Temperature Range -22 to 752°F (-30 to 400°C)

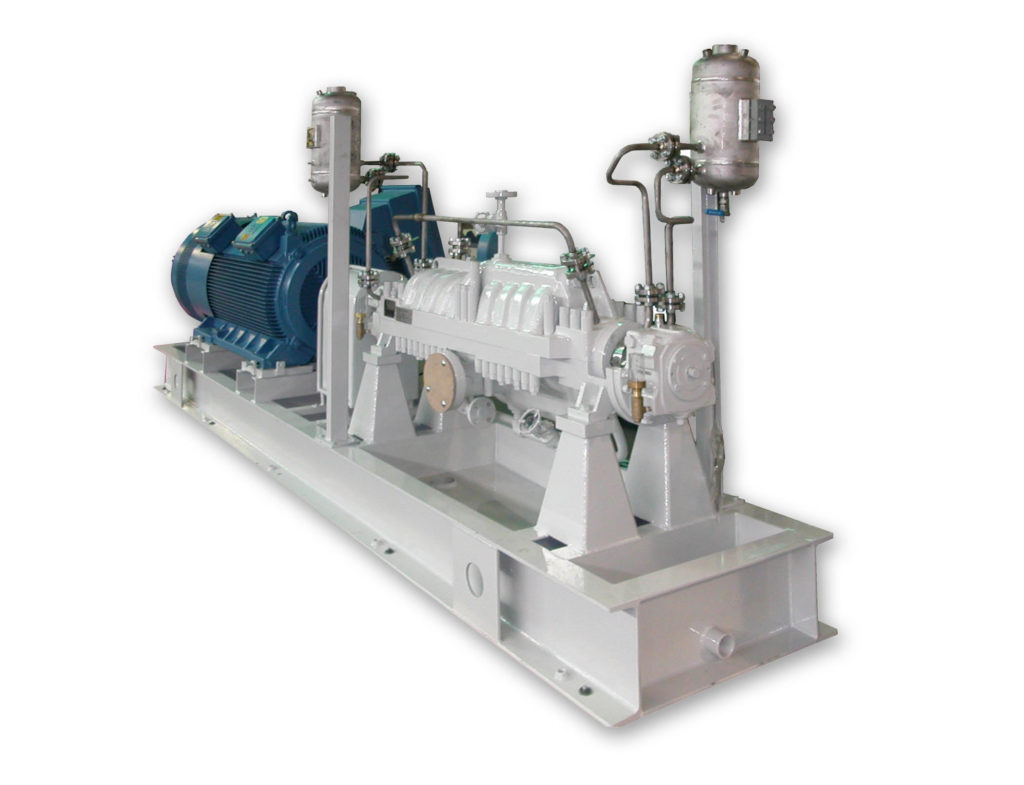

API BB3 multistage centrifugal pump, axially split case with bearings on both ends of the rotating assembly.

- Flows to 2,640 gpm (600 m³/hr)

- Heads to 4,260 ft (1,300 m)

- Maximum Power 2,682 HP (2,000 kW)

- Maximum Suction Pressure 232 psi (16 bar)

- Temperature Range -40 to 410°F (-40 to 210°C)

API OH2 horizontal single or double volute centrifugal pump, centerline mounted, overhung with a single bearing housing.

- Flows to 7,000 gpm (1,280 m³/hr)

- Heads to 1,200 ft (265 m)

- Maximum Power 938 HP (700 kW)

- Maximum Suction Pressure 551 psi (38 bar)

- Temperature Range -238 to 842°F (-150 to 450°C)

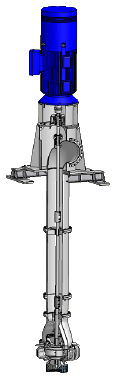

API VS1 vertically suspended multistage centrifugal pump, wet pit, diffuser with single casing.

- Flows to 13,209 gpm (3,000 m³/hr)

- Heads to 1,150 ft (350 m)

- Maximum Power 1,341 HP (1,000 kW)

- Maximum Case Working Pressure 189 psi (13 bar)

- Temperature Range -22 to 482°F (-30 to 250°C)

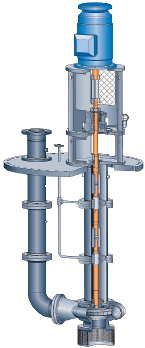

API VS2 vertically suspended double volute centrifugal pump, wet pit, with single casing.

- Flows to 39,600 gpm (10,000 m³/hr)

- Heads to 490 ft (150 m)

- Maximum Power 2,012 Hz (1,500 kW)

- Maximum Case Working Pressure 218psi (15 bar)

- Temperature Range -22 to 482°F (-30 to 250°C)

Marelli VS4 vertically suspended, volute centrifugal pump with discharge column separate from shaft column

- Flows to 7,000 gpm (1,600 m³/hr)

- Heads to 1,180 ft (360 m)

- Maximum Power 939 HP (700 kW)

- Maximum Case Working Pressure 580 psi (40 bar)

- Temperature Range -22 to 752°F (-30 to 400°C)

API VS6 vertically suspended, centrifugal pump with diffuser, double casing and discharge routed through the upright column

- Flows to 30,000 gpm (5,000 m³/hr)

- Heads to 1,800 ft (600 m)

- Maximum Power 1,341 HP, 1,000 kW

- Maximum Case Working Pressure 189 psig (13 bar)

- Temperature Range -22 to 482°F (-30 to 250°C)